After about 6" of freshly fallen snow is shoveled off of the slab and roof, building continues.

Two 4x10 steel beams are welded together on top of 3x3 tube steel posts to support the Dining Room SIP roof and glass curtain walls that will surround it on two sides, above and below.

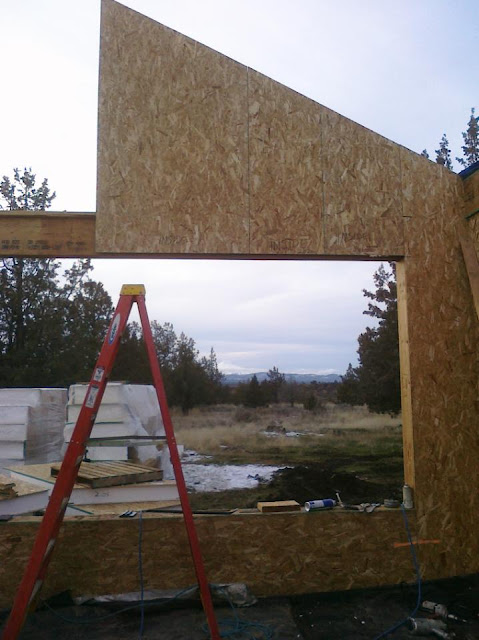

Upper wall SIP's are discovered to be incorrectly cut by the manufacturer, below.

Below, an upper wall SIP wall has some of the core removed to correct a manufacturer's cutting error.

Correction to upper SIP wall is made and installed, below.